➤ The bearing is totally covered with rubber.

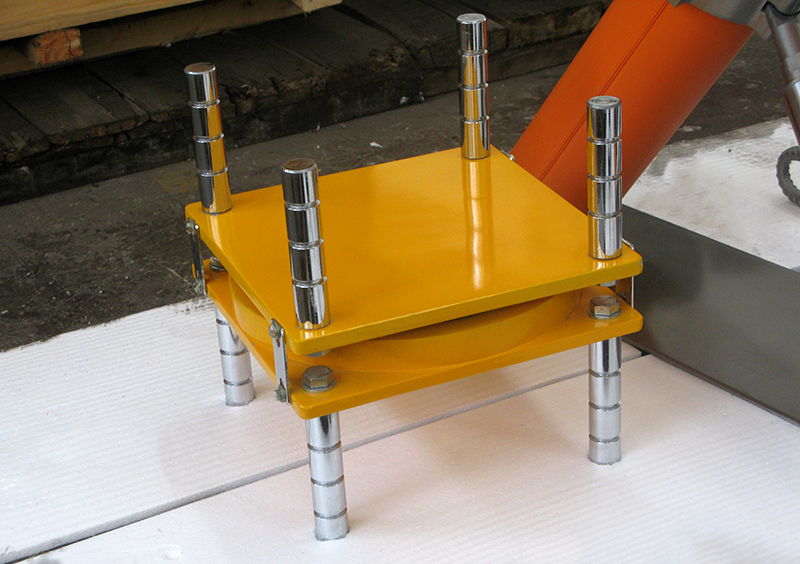

➤ The bearing can be secured against horizontal sliding by means of shear dowels.

➤ Checkered steel sheets are vulcanized onto the upper and lower pad surface.

A bridge bearing is a component of a bridge which typically provides a resting surface between bridge piers and the bridge deck.

A laminated elastomeric bearing is a rubber block vulcanized elastomeric rubber with inner reinforced steel plates .This bearing is a kind of connection between upper structure and lower supporter. An Elastomeric bearing can also be bonded with PTFE plate to satisfy large horizontal movement in one or two directions. Elastomeric bearings are widely used as supports for bridge girders of many types and as seating pads in precast concrete construction. The Internal structure consists of a sandwich of mild steel shims and rubber molded as one unit. Elastomeric bearing pads compress on vertical load and accommodate horizontal rotation and provide lateral shear movement. Elastomeric bearing pads are the most economical solution used in construction of large span bridges and buildings.

Reinforced elastomeric bearing types and steel parts are custom-made. From there it´s possible to supply any special shape and size on request.

➤ The bearing is totally covered with rubber.

➤ The bearing can be secured against horizontal sliding by means of shear dowels.

➤ Checkered steel sheets are vulcanized onto the upper and lower pad surface.

Features: Quality-supervised, tested, successful world-wide and custom-made.

Application: For small to medium loads, small permissible concrete stress, isolation of structures.

Advantages:

➤ Sufficient vertical rigidities to bear and transmit normal loads.

➤ Good flexibilities for rotation in any direction.

➤ Considerable shear deformation to satisfy horizontal movement.

➤ Perfect anti-vibration to reduce the impact of dynamic load.